Custom size HDPE Reusable epoxy resin form

Build your own resin casting HDPE mold. Choose the size and other components like gaskets or clamps. The innovative Resinum HDPE mold! Equipped with a full set of necessary components for creating resin masterpieces. No effort, no sticky mess and no worries about running out of other sealants.

| Category: | Forms for epoxy |

|---|---|

| SKU: | CustomHDPEForm |

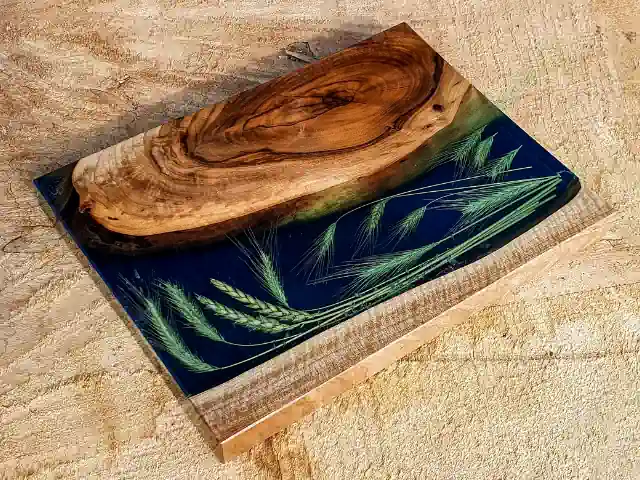

BUILD YOUR OWN HDPE MOLD FOR EPOXY RESIN CATINGS

USE OUR CONFIGURATOR TO CREATE YOUR SIZE HDPE FORM

New design of epoxy resin casting molds

Resinum HDPE epoxy resin forms!

No more cutting, taping & messy silicone!

Complete layout, flexible pouring and safe curing form

The new features of the Resinum HDPE form series allow you to focus on your creative work rather than on technical issues like with other molds!

Thanks to the fact that our molds are made of durable HDPE material, the epoxy resin does not stick to the surface of the mold and allows you to remove the casting from the mold very easily.

There's no need to clean it, seal it, wait for the silicone to cure and it's not sticky - it's just ready for the next casting!

The Resinum HDPE epoxy resin molds series are equipped with many useful features that facilitate safe casting while speeding up mold preparation.

Resinum HDPE form size:

- Variable internal dimensions according to the configurator

- HDPE thickness: 2 cm

Example Resinum HDPE form kit may include:

- Resinum HDPE form, assembled, ready to pour, levelers, leveling feet, T-track system (1 pcs)

- star through hole knobs (6 pcs)

- screws for T-track system (6 pcs)

- movable HDPE clamp bars (3 pcs)

- HDPE spacer blocks (12 pcs - 6 big: 63mm x 38mm, 6 small: 63mm x 13mm)

- user guide for Resinum HDPE form (1 pcs)

- additional bonus codes sent after purchase for future use (send to email)

- 1 Year Warranty

All items can be changed in the configurator below.

Features and advantages of Resinum HDPE mold series:

Resinum HDPE mold is constructed of high-density polyethylene (HDPE). The thickness of the side walls 2cm, which guarantees its stability, the possibility of strong twisting, and prevents bending and deformation.

Proper protection of the mold with a high-quality release agent, such as Honeywax or Stoner, means that you can use the mold in many projects and enjoy the excellent results of your creative work.

The supplied mold is ready to use. If your project requires it, you can additionally use the T-track system clamping bars.

Subsequent casting should be preceded by the use of a high quality separator (release agent).

T-track System

T-rack system can be found in most of our bigger forms.

This ensures the wood remains stable and stationary throughout the curing process, preventing any potential shifting or floating. Moreover, the HDPE composition of the blocks prevents resin adhesion in the event of overflow, preserving the integrity of your resin creations.

You can easily remove clamp bars even if they have been in contact with epoxy resin because they will not stick to each other.

Clamp blocks

This ensures the wood remains stable and stationary throughout the curing process, preventing any potential shifting or floating. Moreover, the HDPE composition of the blocks prevents resin adhesion in the event of overflow, preserving the integrity of your resin creations.

You can easily remove clamp bars even if they have been in contact with epoxy resin because they will not stick to each other.

Leveling feets + bubble levels = leveling system

The mold features a built-in leveling system with four screw-in adjustable feet, ensuring your casting remains level during the process.

Additionally, manual leveling of the mold is possible by adjusting the round feet from the bottom.

In the Resinum HDPE forms series, our molds are equipped with two built-in bubble levelers—one on each of the long and short sides. These aids in visually leveling the mold while working with resin castings using the rotary leveling feet.

2 x Bubble levels

These aids in visually leveling the mold while working with resin castings using the rotary leveling feet.

If you ever need to replace any of those bubble leveling items it is easy to remove and install new one - easy to replace - just push a new bubble level into the hole.

Silicone gasket

Silicone seals are installed to protect the mold from leaks, enduring the corrosive effects of the resin for numerous castings.

The lifespan of these seals can be significantly prolonged by using an additional separator, which helps mitigate wear and tear caused by frequent assembling and disassembling of the mold.

No leaks - everything is PROTECTED!

The twisted mold tightly seals any gaps and keeps the liquid resin in the mold.

Thanks to the groove, the seal stays in place and is flush with the walls and adjacent seals.

Removable side walls

Once the resin has hardened, simply unscrew one short wall to release the casting from the mold. Use a spatula, wide knife, or chisel to separate the bottom part of the casting from the mold, allowing the entire hardened casting to peel away easily.

If needed, unscrew another side wall for efficient removal. Before the next pour, inspect the silicone gasket for damage and replace if needed.

This is photo of example parts of form.

Please be advised

The project, once it has cured, will require additional work for finishing like sanding, polishing or varnishing.

Related products

509,00 zł

285,00 zł

413,00 zł

311,00 zł

Reviews

There are no reviews yet.